FAQ > Customer Provided Glass

There are major safety pitfalls you should be aware of that come into play when installing a customer’s used or new

auto glass part.

•

AGRSS guidelines for installing a used bonded windshield, door, vent, quarter, or rear window back glass

The

term

“used

glass”

can

be

defined

as

a

part

that

has

been

previously

installed.

Each

piece

of

used

glass

must

be

evaluated

on

a

case

by

case

basis.

The

AGRSS

Standard

requires

that

the

part

be

free

of

flaws,

compatible

with

the

new

adhesive

system

and

have

a

traceable

path

to

the

previous

installation

information.

The

adhesive

manufacturer

has

specific

bonding

requirements

to

insure

a

safe,

quality

installation.

The

used

part

can

ONLY

be

used

when

all

questions

about

it

are

answered,

and

the

part

meets

BOTH adhesive manufacturer AND AGRSS Standard requirements.

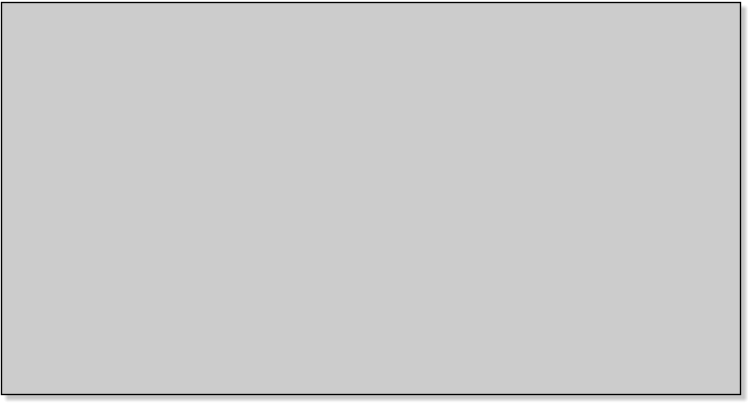

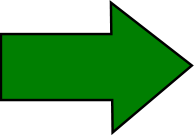

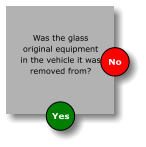

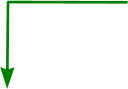

The chart below is the AGRSS standard that all auto glass companies and their technicians are required to follow.

The

AGRSS

Standard

(AGRSS/ANSI

002-2002

Automotive

Glass

Replacement

Safety

Standard)

is

the

first

and

only

North

American

standard

detailing

the

steps

and

procedures

installers

should

take

to

provide

safer

automotive

glass

replacement.

It

is one of the most significant safety developments in the automotive glass industry in the past 50 years.

The

AGRSS

Standard

explains

what

steps

should

be

followed

for

safer

replacements

and

also

sets

up

procedures

for

handling

difficult

or

problem

installations.

It

was

developed

by

a

dedicated

group

of

automotive

glass

industry

professionals

under

the

auspices

of

AGRSS

(Auto

Glass

Replacement

Safety

Standards

Council).

The

entire

development

process

followed

the

procedure

of

the

American

National

Standards

Institute

(ANSI)

to

insure

that

it

was

open

and

complete.

As

a

result,

the

auto-

glass industry has a standard that received input from and belongs to the entire industry, not just one group or company.

It

is

important

that

every

single

person

and

company

involved

in

the

auto-glass

replacement

industry

be

familiar

with

the

AGRSS Standard.

INSTALL GLASS

According to Dow Automotive

Procedures and the

AGRSS Standard

STOP

DO NOT

INSTALL

Does not meet

ARGSS

Standard

STOP

DO NOT

INSTALL

Does not meet

DOW Automotive

Requirments

Did Your company

install the glass in

the vehicle it was

removed from?

No

Yes

Was it installed

according to the

AGRSS Standards?

No

Does the urethane

bonding surface on

the glass meet all of

the following 3

conditions?

•

Freshly Cut

•

Well Bonded

•

Uncontaminated

No

Yes

Does the body-side

bonding surface

meet the same

conditions

No

Yes

Guidelines for

Determining if a

used windshield,

door, quarter or

back glass part

can be installed

?

Are you sure the

method of removal

has not

contaminated the

bonding surface

Yes

No

AGRSS

Surface

contamination

is

and

always

has

been

an

on

going

problem

in

the

auto

glass

industry.

In

2003,

after

a

lot

of

extensive

research,

Dow

Automotive

implemented

a

working

solution

for

the

problem

on

“new”

glass.

Dow's

mission

was

to

define

the

types

of

contamination

and

provide

a

practical

solution

that

is

effective

on

a

wide

range

of

contaminants

and

safe

for

the

auto

glass

technician

doing

the

actual

work.

Dow

concluded

that

the

contamination

could

be

classified

into

one

of

two

types,

"primary"

or

"secondary"

and

that

both

could

be

effectively

treated

by

the

technician

using

materials

typically

on

hand

in

any

properly

equipped

auto

glass

installation

center.

Most

contamination

can

be

classified

as

"primary"

contamination

that

is

the

direct

result

of

the

manufacturing

process

or

shipping

from

the

manufacturer

to

the

distributor's

warehouse.

Dow

developed

a

"wet

scrub"

procedure

for

"new"

auto

glass

parts

a

technician

can

use

that

can

virtually

clean

and

make

just

about

any

"new"

auto

glass

part

usable.

Secondary

contamination,

is

typically

the

result

of

handling

or

transporting

the

glass

part

and

is

usually

easily

treated

with

a

good

"commercial" cleaner.

In

2004

Dow

Automotive

released

the

"wet

scrubbing"

procedure

to

the

technicians

in

the

auto

glass

industry.

This

procedure

uses

a

mist

of

cleaner

that

is

applied

to

the

bonding

area

of

the

glass

that

will

produce

an

indication

of

existing

contamination.

This

particular

cleaner

will

usually

indicate

a

contaminant

is

present

on

the

glass

by

“separating

or

fish

eyeing".

If

this

happens

the

glass

bonding

area

is

cleaned

and

tested

again

by

reapplying

the

cleaner

to

determine

if

the

contaminant

was

removed.

If

the

cleaner

does

not

separate

when

reapplied,

the

contaminant

was

likely

a

"secondary"

contaminant

and

was

successfully

removed

and

the

glass

in

now

ready

for

the

application

of

the

adhesive

system.

If

the

application

of

cleaner

continues

to

"separate

or

fish-

eye"

a

primary

contaminant

is

likely

present

and

more

cleaner

should

be

applied

to

the

bonding

area

and

it

should

be

lightly

scrubbed with a non woven abrasive pad. After that process, the glass part should once again be re-cleaned and reinspected.

If an auto glass technician "wet scrubs" a piece of glass more than three or four times and it does not appear that the contaminant

is removed, Dow recommends that a new piece of glass from a different manufacturer should be used.

By the later half of 2008 Dow Automotive has had nearly five years of proven results with this "wet scrub" process and it

is still being supported by continued testing and well over a million installations.

It

is

highly

possible

that

the

bonding

surface

maybe

unstable

or

contaminated.

Contamination

can

come

from

many

sources

and

can

consist

of

one

or

more

substances.

It

is

difficult

if

not

impossible

for

an

auto

glass

technician

to

accurately

identify

the

contaminant

and

know

of

any

special

treatment

procedure

for

removing

it.

This

was

and

remains

a

problem

even

on

"new

auto

glass".

A

used

glass

that

has

been

out

in

the

world

for

a

number

of

years,

and

removed

by

who

knows

what

method

from

a

vehicle,

has

even

more

hurdles

to

over come

Due to job cost considerations

we do not offer this service for mobile on-site installation, we provide this service only IN House.

•

I already have the auto glass, will Phoenix Glass install it for me?

Yes, but due to economics Phoenix Glass cannot assume responsibility for breakage of your new or used glass. Also note that if we not not

provide the glass to you directly from an auto glass manufacturer or one of our authorized OEM or OEE After market auto glas distributors

we cannot warranty the glass itself.

Copyright 2013 © Phoenix Glass, Inc. All Rights Reserved

Revised June 2023

Please Like Us

on Facebook

Was the glass

original equipment

in the vehicle it was

removed from?

No

Yes

Yes